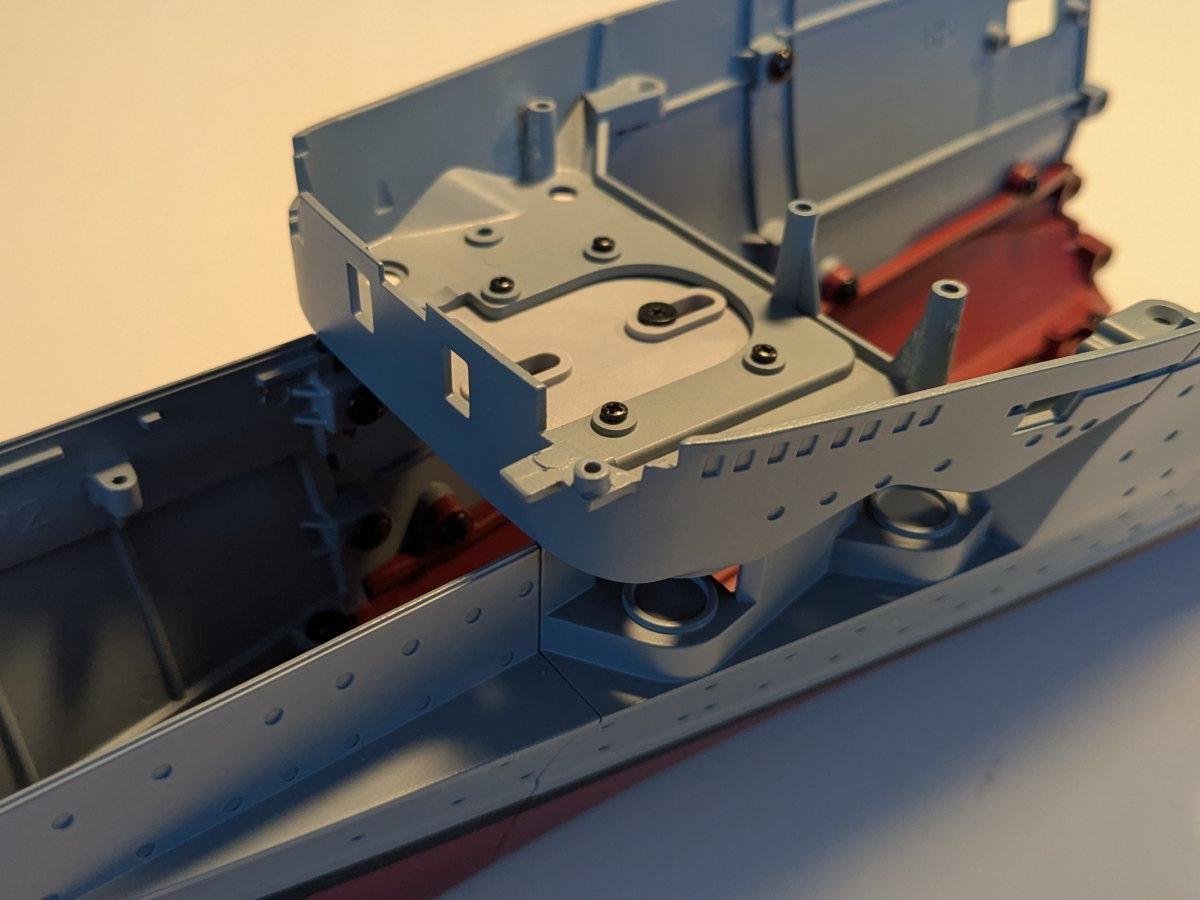

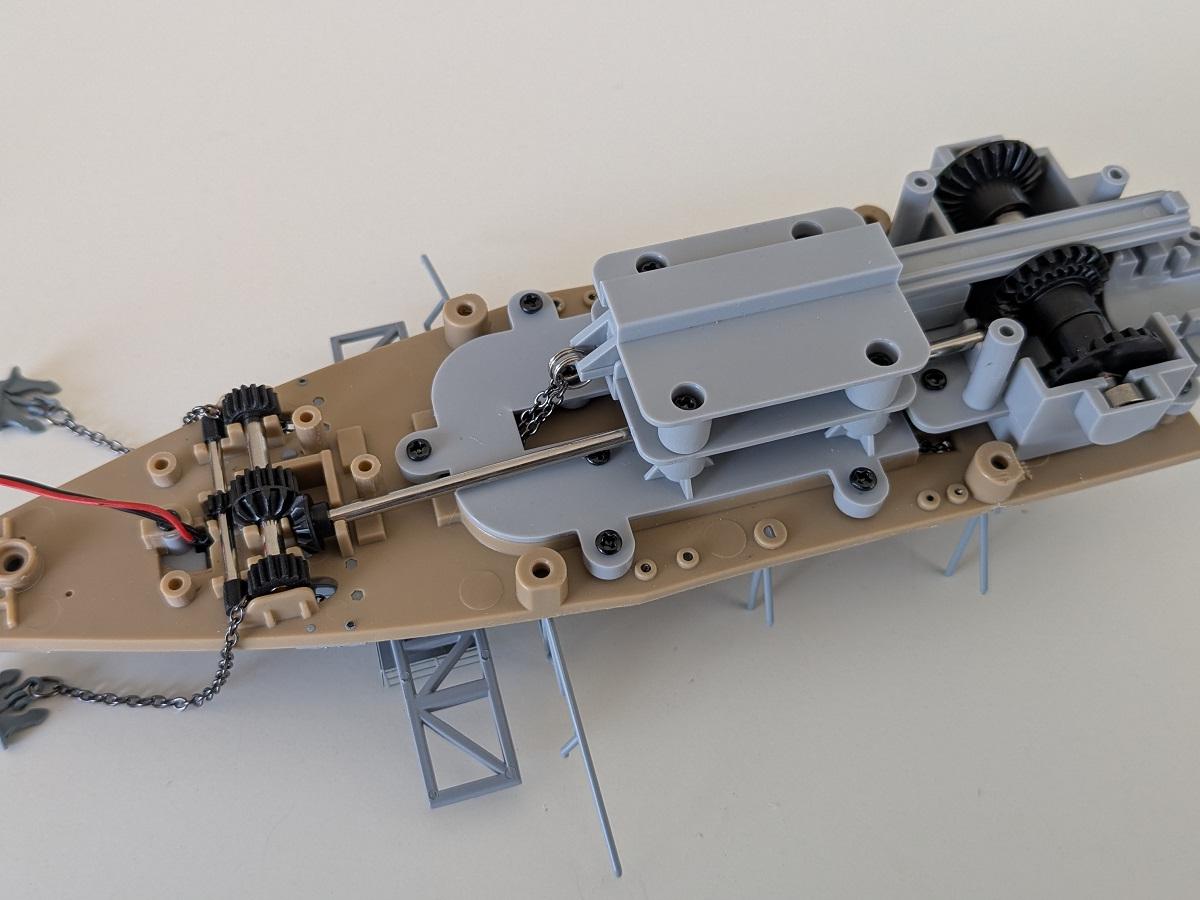

Construction begins with the initial assembly of the bow and a Ju 87 dive bomber, including electrical testing of the aircraft's propeller. The model's foremost deck is then built, featuring a 3.7 cm anti-aircraft gun with a blinking LED for simulated firing. Hull construction commences with the addition of keel and hull sections. As the build progresses, a second Ju 87 is added, and photo-etched parts are used for railings and platforms. The final steps focus on the moving anchor mechanism, with the installation of both anchors, their chains, and a complex system of cogwheels and spools below the deck.