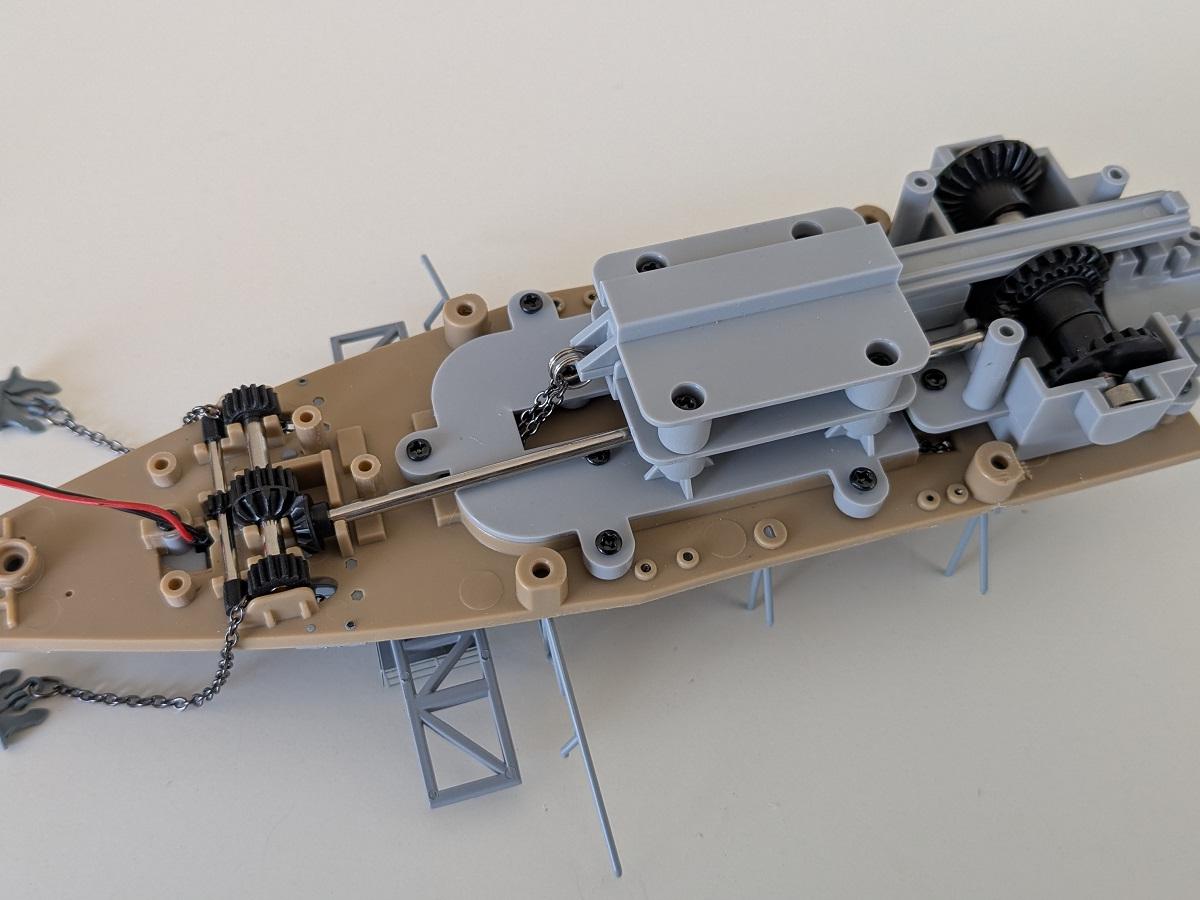

During these stages, the focus shifts from internal mechanisms to major structural and functional assemblies. The anchor system is completed and tested, along with further detailing of the aircraft complement. The forward hull is then built up with multiple hull and keel sections, greatly increasing the model’s stability and weight.

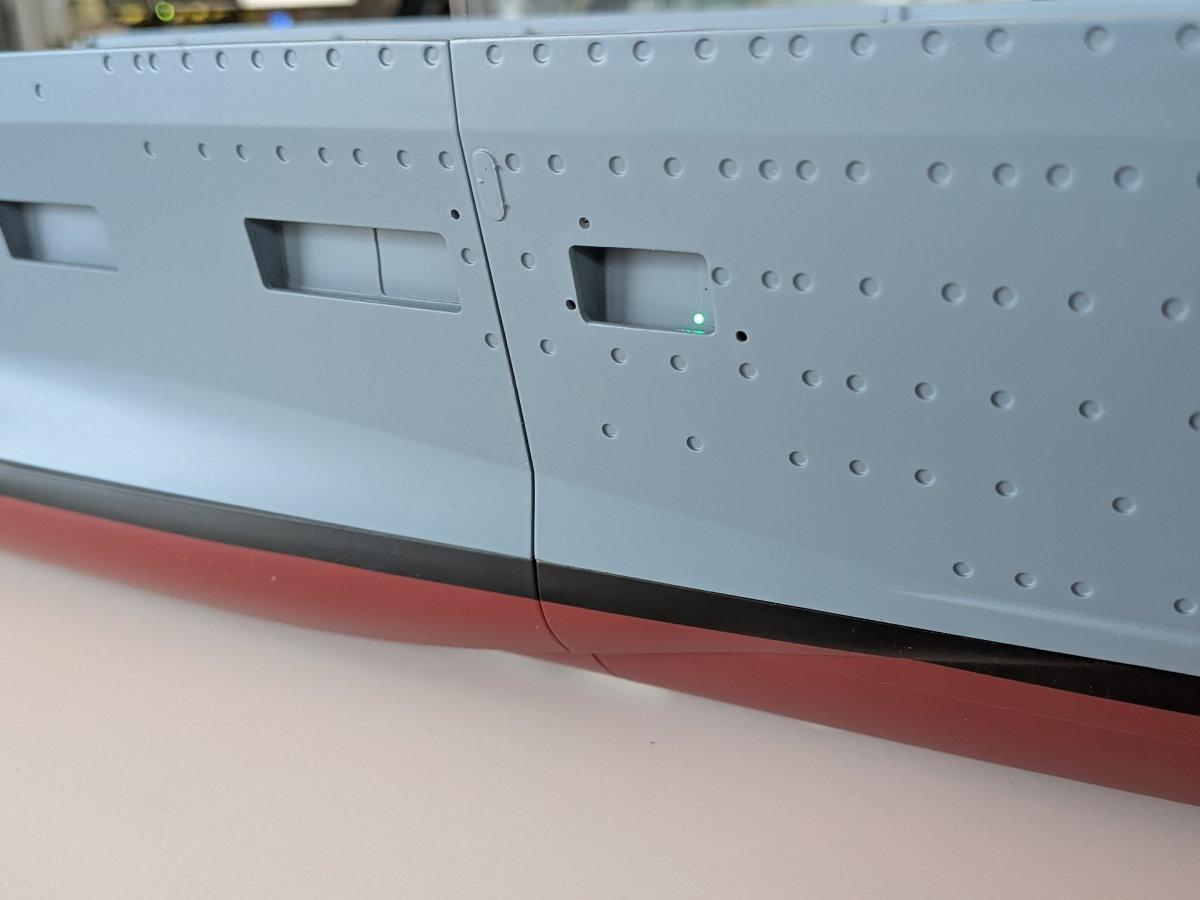

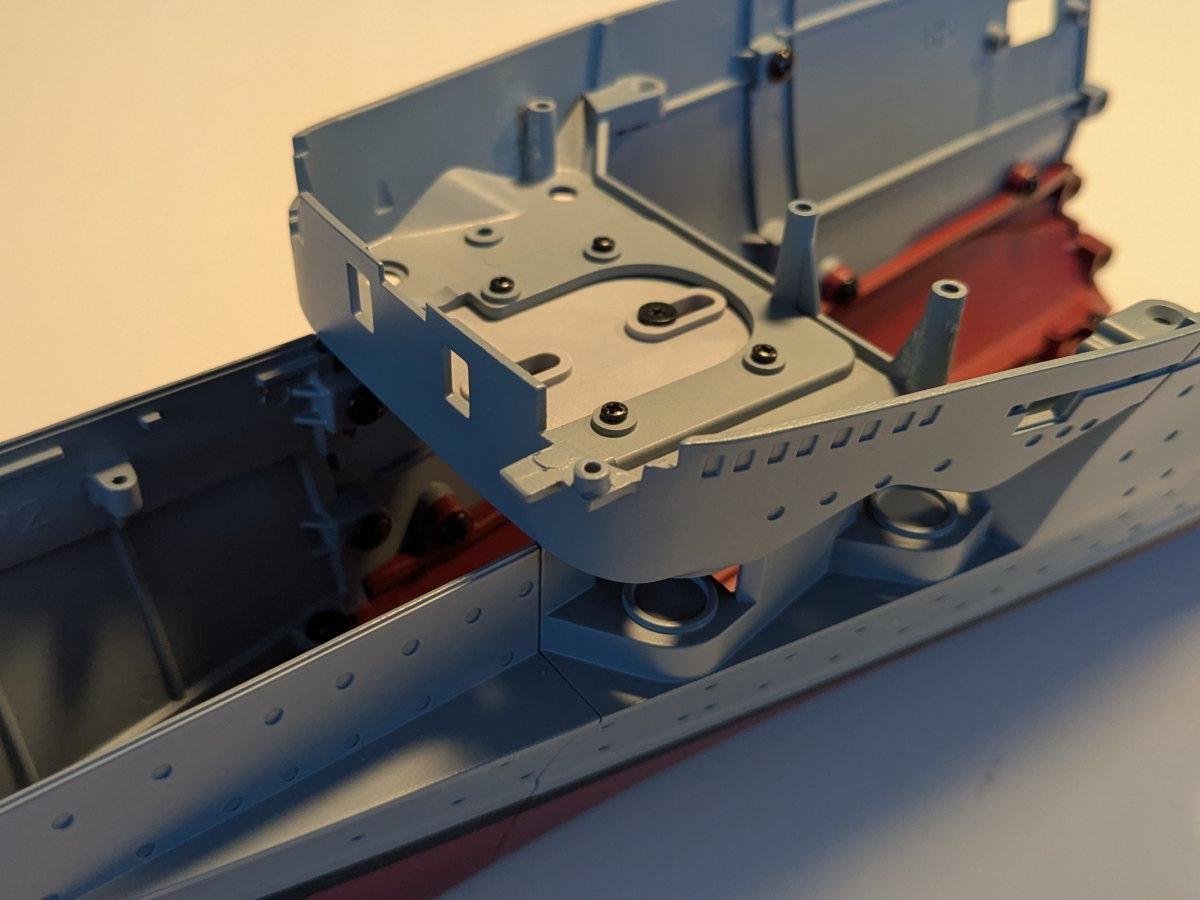

Work then progresses to the flight deck, where the wooden deck covering, lighting, and extensive underside detailing are added. Both catapults, one functional and one static, are fully assembled, motorized, tested, and integrated into the deck along with additional equipment. By the end of this phase, the first stages of the forward 15 cm gun turret assembly also begin, marking the transition toward the ship’s main armament.